Hi everyone,

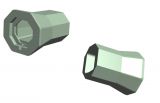

I'd like to share my experiment about extending my racquet by 3D printing a 1 inch buttcap. All the buttcaps are solid, no hollow inside. The racquet I decided to try is the Yonex Vcore Tour F 93. My first prototype is quite "traditional". It wraps over the handle so the handle is bigger than original. Because I flare the buttcap too much, I had to re-design it. This one weights about 37gr.

While I was making the second one, I thought to change the design a bit. This time there are parts that go into the hairpin. So that the handle won't be enlarged. This buttcap weights at 33gr.

Some pictures to compare between the buttcaps:

I need to file the buttcap a bit so it is able to stay flushed in the original handle. The buttcap looks a bit rough but still nice. I forgot to weight it again. I assume it weights about 30gr.

I tried the hand staple gun in the other buttcap but failed. So this time, I only used glue (with the name Pattex 100%). I applied some pressure to keep buttcap and handle together, then left them in a day.

Finally, I wrapped few rounds of electrical tape to feel more secured, then replacement grip and overgrip. Here are some pictures of the finished racquet:

I just played in 2 hours but it feels absolutely solid. At some times, I thought that the racquet is 28 inches originally. There's no sign of breakage or loose.

About the racquet itself, it weights at 362gr with everything ready to play. 31,5cm balance. Swingweight at 356. Lots of comfort playing with this racquet seriously. My arm was less sore after the session. 'Let the racquet to the work' really works. This Vcore Tour F 93 originally, has the strange stiff, rough feeling when I don't hit the balls at sweet spot. However, after extension, I don't have that feeling anymore. Returning heavy balls is very easy, especially when I hit at sweet spot. Power is great and it's one of the reasons why I attempted to lengthen a mid racquet while I didn't lose any control. In contrast, I felt that I have better control since I use my muscle less to generate power but more to control the racquet. I serve faster than ever before, as I can anticipate. Comparing to the Wilson Blade SW 104 (which is also 28 inches long), my racquet is less demanding. The SW 104 needs more work to swing it.

That's all I can think of to write at the moment. Would love to hear opinions from fellows players .

.

I'd like to share my experiment about extending my racquet by 3D printing a 1 inch buttcap. All the buttcaps are solid, no hollow inside. The racquet I decided to try is the Yonex Vcore Tour F 93. My first prototype is quite "traditional". It wraps over the handle so the handle is bigger than original. Because I flare the buttcap too much, I had to re-design it. This one weights about 37gr.

While I was making the second one, I thought to change the design a bit. This time there are parts that go into the hairpin. So that the handle won't be enlarged. This buttcap weights at 33gr.

Some pictures to compare between the buttcaps:

I need to file the buttcap a bit so it is able to stay flushed in the original handle. The buttcap looks a bit rough but still nice. I forgot to weight it again. I assume it weights about 30gr.

I tried the hand staple gun in the other buttcap but failed. So this time, I only used glue (with the name Pattex 100%). I applied some pressure to keep buttcap and handle together, then left them in a day.

Finally, I wrapped few rounds of electrical tape to feel more secured, then replacement grip and overgrip. Here are some pictures of the finished racquet:

I just played in 2 hours but it feels absolutely solid. At some times, I thought that the racquet is 28 inches originally. There's no sign of breakage or loose.

About the racquet itself, it weights at 362gr with everything ready to play. 31,5cm balance. Swingweight at 356. Lots of comfort playing with this racquet seriously. My arm was less sore after the session. 'Let the racquet to the work' really works. This Vcore Tour F 93 originally, has the strange stiff, rough feeling when I don't hit the balls at sweet spot. However, after extension, I don't have that feeling anymore. Returning heavy balls is very easy, especially when I hit at sweet spot. Power is great and it's one of the reasons why I attempted to lengthen a mid racquet while I didn't lose any control. In contrast, I felt that I have better control since I use my muscle less to generate power but more to control the racquet. I serve faster than ever before, as I can anticipate. Comparing to the Wilson Blade SW 104 (which is also 28 inches long), my racquet is less demanding. The SW 104 needs more work to swing it.

That's all I can think of to write at the moment. Would love to hear opinions from fellows players

Last edited: