lethalfang

Professional

There always seems to be questions regarding how accurate a dropweight tensioner is. In simple words, very accurate.

I will present here the physics governing a dropweight tensioner.

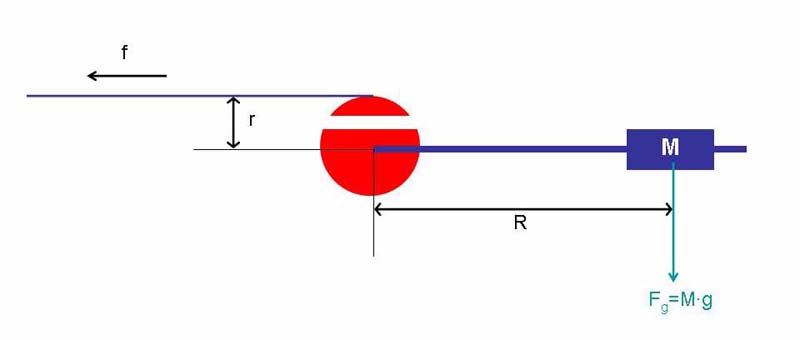

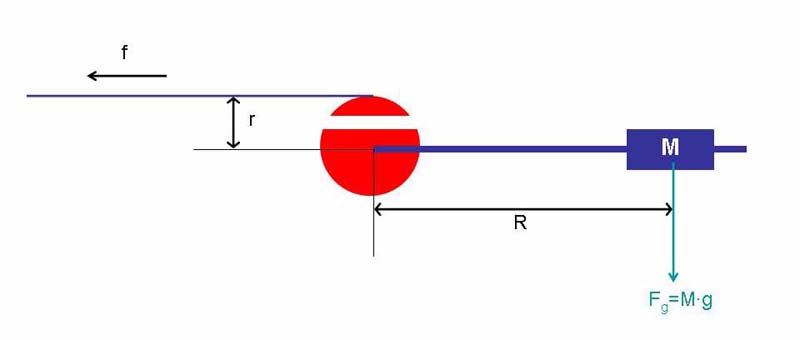

Here is a schematic of a string being tensioned by a dropweight machine:

We know from physics that, in order to rotate an object such as a rotational tensioner indicated in the schematic as a red wheel, you need to apply a torque.

torque = force x distance

Newton has figured out that force = Mass x acceleration. On earth, each object with a mass will exert a downward force equal to the product of its mass (M) and the earth's gravitational acceleration denoted as "g."

Therefore, the gravitational force (Fg) provided by a dropweight is M x g, as indicated with green letters on the schematic.

If we also know the distance (R) between the center of the Mass and the axis of the rotation for the tensioner, we can figure out the torque. Remember that torque = force x distance, therefore the torque exerted by the dropweight (on the right side of the schematic) is:

torque right side = M x g x R

This is why as you move the dropweight farther from the center, you pull a greater tension on the string.

When the string is being tensioned, the rotational tensioner does not move. That's because the torque exerted by the dropweight is balanced by the torque exerted on it by the string.

Again, the equation for torque does not change: torque = force x distance.

On the left side, the distance in question is the distance between the center of the rotational axis and where the string applies its force. In other words, the radius of the tension head is the distance (r) of interest. The force in this case is the "reference tension" imparted on the string.

When the tension head is at rest, it means the torque on the left side equals the torque on the right side, therefore we can set up an equation:

torque left side = torque right side, therefore

f x r = M x g x R

Play with that equation a little bit, you get:

f = (M g / r) R

Mass (M), gravitational acceleration (g), and the tensioner's radius (r) are all constant, i.e. they never change. Therefore, the reference tension is directly proportional to the distance (R). That's why a dropweight tensioner is simple and requires no calibration, and is impeccably accurate.

Now you must be asking this question: what if the tension bar isn't exactly horizontal?

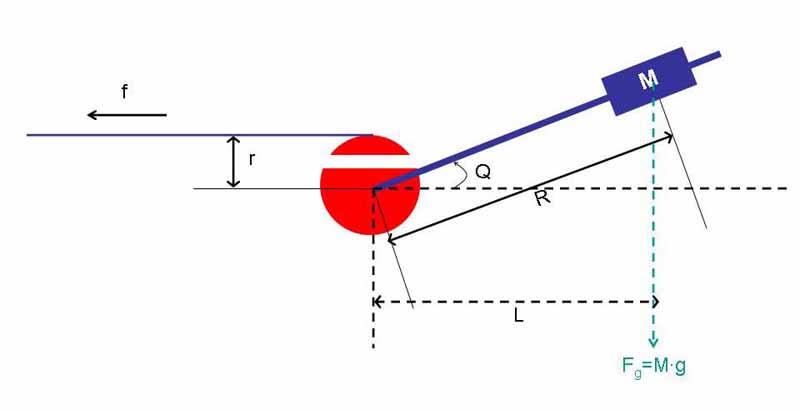

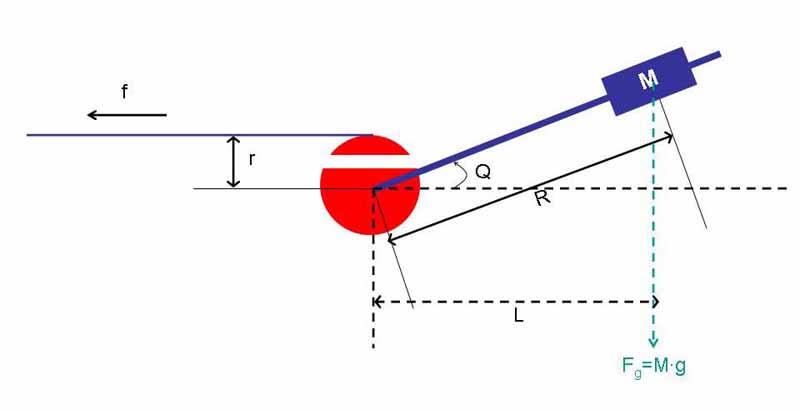

Here is another schematic to show you the error when the tension bar is not horizontal:

Remember again: torque = force x distance

Gravity "does not know" if the bar is horizontal, but gravity does know the true distance between the center axis of the tensioner and the center of Mass of the dropweight.

In other words, the torque for the right side should be replaced by this equation instead:

f x r = M x g x L, where L is the horizontal distance between the center of the tensioner to the dropweight.

We know from trigonometry how to related R to L, that if the tension bar is resting at an angle Q, then L = (cos Q) R.

Thus, to improve upon the original equation, the tension you're imparting on the string (f) at any angle is:

f = (M g / r) L , or

f = (M g / r) (cos Q) R

At Q = 0, cos Q = 1. Therefore, the number you see on the tension bar, if the bar is resting at exactly horizontal, is exactly the tension you're imparting on the string.

Cos 5 = cos (-5) = 0.996, i.e. if you set the mark at 60 lb, but the bar is either 5 degrees above or below horizontal, the actual tension is 59.8 lb.

Cos 10 = cos (-10) = 0.985, i.e. if you want 60 lb., you get 59 lb.

That's why the advice is that, if the bar is close enough to horizontal, your tension really is close enough to what you want.

Two additional questions you guys might be wondering:

1) I use the center of mass of the dropweight to calculate the distance, but the mass of a dropweight isn't at a point. It spans a distance of 3 inches. Does that introduce an error in my calculation?

The answer is no. This simplification does not introduce error.

If you don't want to take my words for it, I will prove it mathematically.

First let's clarify one thing. In everyday life, we use mass terms as force, i.e. 1 pound of force, etc., the reason is that when we say "1 pound of force," it is implicit that we mean 1 pound of mass multiplied by the gravitational acceleration. For instance, 1 kg of force really means 1 kg x 9.8 m/sec^2 = 10 Newtons.

Let's simply the equations and use M as force.

By definition, torque in integration form is:

Also, by definition, the point of Center of Mass (rCoM) is:

If you multiply the radius of Center of Mass by Total Mass, it's exactly torque.

2) The tension bar itself weights a few ounces, does that introduce an error?

In fact, it does, but the mass of the tension bar << mass of the dropweight, thus the effect is negligible.

Also keep in mind that the mass of the tension bar does not change, either. Thus, it is not a variable for your stringing machine. The error can simply be corrected in my equation by adding a small correction to the Mass, by taking into account the mass of not only the dropweight, but also the tension bar.

I will present here the physics governing a dropweight tensioner.

Here is a schematic of a string being tensioned by a dropweight machine:

We know from physics that, in order to rotate an object such as a rotational tensioner indicated in the schematic as a red wheel, you need to apply a torque.

torque = force x distance

Newton has figured out that force = Mass x acceleration. On earth, each object with a mass will exert a downward force equal to the product of its mass (M) and the earth's gravitational acceleration denoted as "g."

Therefore, the gravitational force (Fg) provided by a dropweight is M x g, as indicated with green letters on the schematic.

If we also know the distance (R) between the center of the Mass and the axis of the rotation for the tensioner, we can figure out the torque. Remember that torque = force x distance, therefore the torque exerted by the dropweight (on the right side of the schematic) is:

torque right side = M x g x R

This is why as you move the dropweight farther from the center, you pull a greater tension on the string.

When the string is being tensioned, the rotational tensioner does not move. That's because the torque exerted by the dropweight is balanced by the torque exerted on it by the string.

Again, the equation for torque does not change: torque = force x distance.

On the left side, the distance in question is the distance between the center of the rotational axis and where the string applies its force. In other words, the radius of the tension head is the distance (r) of interest. The force in this case is the "reference tension" imparted on the string.

When the tension head is at rest, it means the torque on the left side equals the torque on the right side, therefore we can set up an equation:

torque left side = torque right side, therefore

f x r = M x g x R

Play with that equation a little bit, you get:

f = (M g / r) R

Mass (M), gravitational acceleration (g), and the tensioner's radius (r) are all constant, i.e. they never change. Therefore, the reference tension is directly proportional to the distance (R). That's why a dropweight tensioner is simple and requires no calibration, and is impeccably accurate.

Now you must be asking this question: what if the tension bar isn't exactly horizontal?

Here is another schematic to show you the error when the tension bar is not horizontal:

Remember again: torque = force x distance

Gravity "does not know" if the bar is horizontal, but gravity does know the true distance between the center axis of the tensioner and the center of Mass of the dropweight.

In other words, the torque for the right side should be replaced by this equation instead:

f x r = M x g x L, where L is the horizontal distance between the center of the tensioner to the dropweight.

We know from trigonometry how to related R to L, that if the tension bar is resting at an angle Q, then L = (cos Q) R.

Thus, to improve upon the original equation, the tension you're imparting on the string (f) at any angle is:

f = (M g / r) L , or

f = (M g / r) (cos Q) R

At Q = 0, cos Q = 1. Therefore, the number you see on the tension bar, if the bar is resting at exactly horizontal, is exactly the tension you're imparting on the string.

Cos 5 = cos (-5) = 0.996, i.e. if you set the mark at 60 lb, but the bar is either 5 degrees above or below horizontal, the actual tension is 59.8 lb.

Cos 10 = cos (-10) = 0.985, i.e. if you want 60 lb., you get 59 lb.

That's why the advice is that, if the bar is close enough to horizontal, your tension really is close enough to what you want.

Two additional questions you guys might be wondering:

1) I use the center of mass of the dropweight to calculate the distance, but the mass of a dropweight isn't at a point. It spans a distance of 3 inches. Does that introduce an error in my calculation?

The answer is no. This simplification does not introduce error.

If you don't want to take my words for it, I will prove it mathematically.

First let's clarify one thing. In everyday life, we use mass terms as force, i.e. 1 pound of force, etc., the reason is that when we say "1 pound of force," it is implicit that we mean 1 pound of mass multiplied by the gravitational acceleration. For instance, 1 kg of force really means 1 kg x 9.8 m/sec^2 = 10 Newtons.

Let's simply the equations and use M as force.

By definition, torque in integration form is:

Also, by definition, the point of Center of Mass (rCoM) is:

If you multiply the radius of Center of Mass by Total Mass, it's exactly torque.

2) The tension bar itself weights a few ounces, does that introduce an error?

In fact, it does, but the mass of the tension bar << mass of the dropweight, thus the effect is negligible.

Also keep in mind that the mass of the tension bar does not change, either. Thus, it is not a variable for your stringing machine. The error can simply be corrected in my equation by adding a small correction to the Mass, by taking into account the mass of not only the dropweight, but also the tension bar.

Last edited: