Not disagreeing with anyone; I would take a Stringway and not worry about the slight variance. Still, I wonder how many people who don't think Stringway's +/- 5% variance is a big deal would give the same pass to an Eagnas machine with the same variance?

Well, it's actually closer to 2% to 3% on most occasions, and 0% when the bar is horizontal. I think the machine has so many other redeeming qualities, like the mounting system and solid build quality, which make up for this.

As people already mentioned, the "big picture" is that the overall quality of the string jobs on these machines is still excellent. I am in agreement, especially now that I know how to adjust things. But I do want to point out that had I not known what I now know about my machine, that might not have been the case. For example, the concorde system allows for friction free pulling, and is likely much more accurate that on the machines where the string has to go around the throat. However, had I not known about the tension variance, and let the bar drop below horizontal, I would have lost 3 lb to 4 lb of tension on the center mains! That really adds up when you take all the center mains into account. Probably would have made my string jobs feel better due to the extra sweet spot.

I would like to make three points of why this discussion is important.

1. The advertised exact tension at every angle, meaning that the stringer doesn't have to worry about the angle, which is a huge time saver and the main selling point of the machine. I think people have the right to know that they are getting something that due to manufacturing tolerances may not give them exact tension. However, I don't see Stringway changing this anytime soon, as I said, this is the main selling point of the machine. As someone already mentioned, the Pioneer DC Plus is looking a whole lot better at its price points, especially when one can pick up a used one for a few hundred.

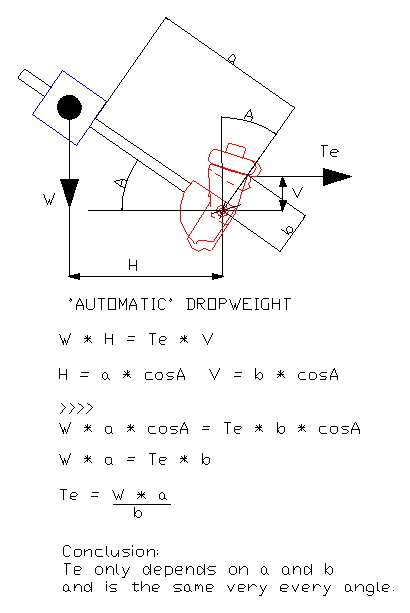

2. Thanks to some very intelligent people on here that really know their math, looks like we are getting to the bottom of what seems to be the cause of this variance. Fred Timmer tried to explain this to me after I send him the video demonstrating that I was getting exact same tension when the angle of the string entered the tension head from below the level of the mounting platform. I told him that something inside my tension head was not calibrated to the level of the platform. He said it had nothing to do with calibration, but I could not understand what he meant, maybe his explanation will help those who are better at seeing the theoretical aspects of this. Fred wrote:

"The basis idea about our tensioner is that it pulls the string through the grommet as horizontal as possible. This means that the gripper pushes the string down wards in the situation that the lever is above horizontal. Because of the angle the horizontal lever of the string gets smaller so the tension goes up when the lever is far above horizontal. In your test you compensate for this angle by moving the fixed point of the string downwards and therefore changing the angle of the string coming out of the gripper. This results in longer lever so the tension goes down.

But it is not possible to combine this situation when the tensioner is on the level of the stringbed what we want. It has nothing to do with the calibration of the machine.

When I sent him the video with books, he also seemed to undestand what was happening, and gave me a good explanation, but again I am just not really sure what he meant.

"Why do the books have influence? The importance of the tensioner is the relation between the angle of the lever and the angle “with the earth” and of the out going string.

* For the angle of the lever the angle in relation to the horizontal line is important. The driving force of the system is maximum when the lever is horizontal creating the maximum torque.

* For the outgoing string the angle in relation to the frame of the machine is important. With the books you rotate the angle of the out going string and the frame. But the angle of the lever “with the earth” stays the same. So you actually rotate the tension head compared to the angles that were used before. This means that the push down effect in the above horizontal range, which is caused by the large radius of the upper jaw, is less."

So as you can see Fred has been pretty patient with me, and he seems to understand the issues (even so I don't undersatnd his explanations), so I am sure if it was within his capacity to fix this he probably would. Seems like the required precision would be too much for the manufacturing tolerances, afterall, he is not making thigs for NASA.

Still, I do wonder if they could introduce some sort of individual calibration process, or add some user adjustments, that would be able to correct this issue, since they currently rely solely on the integrity of the design. I think that the advertising by Stringway and the high price of their machines should warrant somthing like this.

3. Finally, the last point is that everyone should test their machine and know what it is capable of and what are its weakneses, this is unique to every machine. This way you can get the most out of it.