Stringway Official

Rookie

This might seem a bit silly, but I'm having trouble figuring out how much I should be tightening the racquet with the four top arms. I know on a 6 point mount you have to be very careful not to overtighten so I'm a bit wary with how much force I use.

Hi Nostradamus,

Imo asking is never silly.

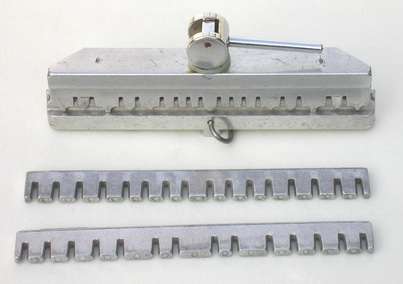

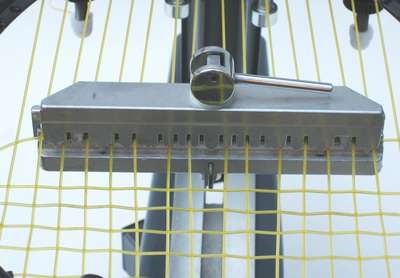

The function of our “clamp down hooks” is completely different from the function of the outside supports on 6 point machines.

The hooks only take care to keep the racquet behind the white supports, which avoid the deformation of the racquet.

Fixing them very tight is wrong and useless.

When they are too loose that might result in a little sliding of the racquet when most crosses are done, but this has no negative effect at all on the racquet.

Is there a risk of warping the racket if you don't use this machine correctly ?

No risk at all.

One more advise:

To obtain the minimum deformation of the racquet it is important to choose the right tensions for mains and crosses. You can use our online Tension Advisor for this.

Important check: compare length and width of the racquet before and after stringing when they are the same the tensions were right.

The position of the supports must be right when you place the racquet back on the supports after stringing.