You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stringway ML 100

- Thread starter djones23l

- Start date

Irvin

Talk Tennis Guru

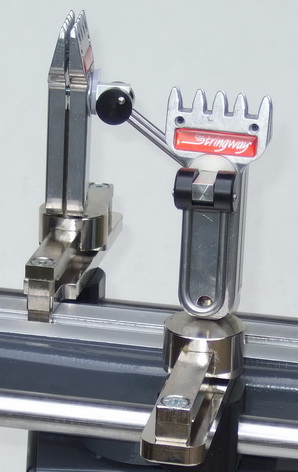

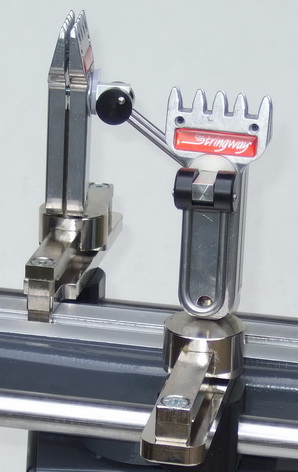

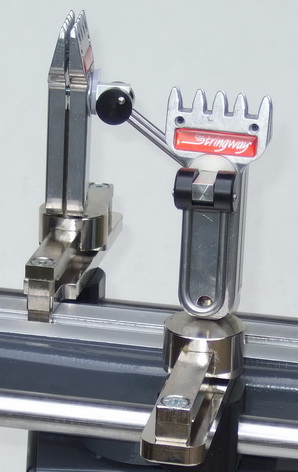

Watch the video the double action T98 require two actions to clamp the string and clamp base, while the single action T92 requires one action.

http://www.youtube.com/watch?v=9thV_d_BC-0

Irvin

http://www.youtube.com/watch?v=9thV_d_BC-0

Irvin

I have a 5 year old LaSerFibre which is now the Stringway M90 - note the old LaSerfibres are now the new Stringways - exact same machine. I think it is the best drop weight on the market. Here's what I like:

1. It is true constant pull at any angle. You don't have to position the drop arm at 90 degree angle to have the correct tension which makes it easier and faster. Also, constant pull is better than crank or electric lock-out as constant pull provides tighter string jobs and they keep their tension better as some stretch is taken out on the machine.

2. It is built very well. A steel weight on the end of a steel bar is more durable than an electric motor. Gravity on a steel weight is also pretty consistent as gravity does not change over time like an electric motor or a spring driven crank system.

3. Clamps are also built like a tank and easy to use. 2 action - they slide and swivel which makes it easy to position.

4. You can get a brake which makes it easy to do the Prince 0 port racekts.

I like the Stringways - they are very good machines.

A word of caution, if you look at LaSerFibre, please be forewarned that their customer service is lacking. They will take your $ and delivery may take many months. They will also ignore e-mail and phone calls. Stringway seems to be the better distributor at the moment. I have ordered a brake from Stringway and customer service was very good.

1. It is true constant pull at any angle. You don't have to position the drop arm at 90 degree angle to have the correct tension which makes it easier and faster. Also, constant pull is better than crank or electric lock-out as constant pull provides tighter string jobs and they keep their tension better as some stretch is taken out on the machine.

2. It is built very well. A steel weight on the end of a steel bar is more durable than an electric motor. Gravity on a steel weight is also pretty consistent as gravity does not change over time like an electric motor or a spring driven crank system.

3. Clamps are also built like a tank and easy to use. 2 action - they slide and swivel which makes it easy to position.

4. You can get a brake which makes it easy to do the Prince 0 port racekts.

I like the Stringways - they are very good machines.

A word of caution, if you look at LaSerFibre, please be forewarned that their customer service is lacking. They will take your $ and delivery may take many months. They will also ignore e-mail and phone calls. Stringway seems to be the better distributor at the moment. I have ordered a brake from Stringway and customer service was very good.

It's also worth noting that Laserfibre is no longer distributing the Stringway machines under their logo. If you check out the Laserfibre website they have a more typical mounting system though they appear to still have the Stringway style of drop weight. If I remember right, Alpha Tennis is the new distributor of Stringway in the US.

Overheadsmash

Professional

I have a ML120 with the single action clamps and am totally happy with it. The drop weight it very easy to use and it is a straight pull. I'm glad I got the 120 which is on a stand though - I would not like to string on a tabletop.

Very well built machine too.

Very well built machine too.

I bought a tool stand from Grizzly Tools for $50 over the internet and it fits my ML90 very well. The stand has a wood table top and I just place the machine on top. The legs are gun metal gray and they match the machine like they come in a set. No tool tray but I could easily add one if I wanted - I just set the tools on the table top around the stand.

Peppershaker

Rookie

I purchased the ML100 w/stand and really enjoy the machine. Would have purchased the ML120 w/Concorde but thought that I wanted a table top machine....but now can't see ever taking the unit off the stand.

For a drop-weight machine it is at the upper price range, but the design of the unit (single drop), the build/quality (excellant) and the ease of use well worth it.

As I understand it the Concorde system when activated raises the handle end of the racquet to better align the string to the drop weight mechanism and eliminate possible friction from the string rubbing agains the handle/frame. Also believe that when activated provides a full 360 rotation.

Not having either feature does not take away from the machines in any way but certainly does look like a slick feature to have. It's now available as an option and as an upgrade, very tempted to order one and will probably do so.

For a drop-weight machine it is at the upper price range, but the design of the unit (single drop), the build/quality (excellant) and the ease of use well worth it.

As I understand it the Concorde system when activated raises the handle end of the racquet to better align the string to the drop weight mechanism and eliminate possible friction from the string rubbing agains the handle/frame. Also believe that when activated provides a full 360 rotation.

Not having either feature does not take away from the machines in any way but certainly does look like a slick feature to have. It's now available as an option and as an upgrade, very tempted to order one and will probably do so.

ML100 with a single action clamping

I have had this machine for a while and clamping system sucks quite badly. They have engineered oddly. They have user plastic in main slider which takes the main load. The result is that clamping isn't stiff enough and the hole clamping system yields way too much. I think when using higher stringing tensions eg. tennis racket stringing the result isn't good enough. It can't be.

I have renewed the hole clamping system and now it is stiff enough and the results are exellent.

The tension system is good. That's why it was worth to renew the clamping system.

The way I have done the clamping system is way too expensive to do in a commercial meaning. Lots of machined parts eg. The original system is made by standard bars avoiding machining.

I have had this machine for a while and clamping system sucks quite badly. They have engineered oddly. They have user plastic in main slider which takes the main load. The result is that clamping isn't stiff enough and the hole clamping system yields way too much. I think when using higher stringing tensions eg. tennis racket stringing the result isn't good enough. It can't be.

I have renewed the hole clamping system and now it is stiff enough and the results are exellent.

The tension system is good. That's why it was worth to renew the clamping system.

The way I have done the clamping system is way too expensive to do in a commercial meaning. Lots of machined parts eg. The original system is made by standard bars avoiding machining.

Joonas

Semi-Pro

I have had this machine for a while and clamping system sucks quite badly. They have engineered oddly. They have user plastic in main slider which takes the main load. The result is that clamping isn't stiff enough and the hole clamping system yields way too much. I think when using higher stringing tensions eg. tennis racket stringing the result isn't good enough. It can't be.

I have renewed the hole clamping system and now it is stiff enough and the results are exellent.

The tension system is good. That's why it was worth to renew the clamping system.

The way I have done the clamping system is way too expensive to do in a commercial meaning. Lots of machined parts eg. The original system is made by standard bars avoiding machining.

What do you mean by clamping system? Actual string clamps or the racket mounting system? Would you elaborate as I am curious to understand what and how did you improve?

The hole clamping system

Clamp, clamp base, slider system 1 and slider system 2. The hole chain.

If you lookout the clamp it self the thinnest poist is there where it should be the thickest. Not really the cleverest design. Lookout how Babolat has built their clamping bases.

What do you mean by clamping system? Actual string clamps or the racket mounting system? Would you elaborate as I am curious to understand what and how did you improve?

Clamp, clamp base, slider system 1 and slider system 2. The hole chain.

If you lookout the clamp it self the thinnest poist is there where it should be the thickest. Not really the cleverest design. Lookout how Babolat has built their clamping bases.

And what I did

I replaced the main plastic slider with the aluminium one. I changed the clamps and their bases to the "Babolat" style. I changed the slider 1 main beam to lower and stiffer. And of course counterpart also.

In a one word the hole clamping system.

What do you mean by clamping system? Actual string clamps or the racket mounting system? Would you elaborate as I am curious to understand what and how did you improve?

I replaced the main plastic slider with the aluminium one. I changed the clamps and their bases to the "Babolat" style. I changed the slider 1 main beam to lower and stiffer. And of course counterpart also.

In a one word the hole clamping system.

I replaced the main plastic slider with the aluminium one. I changed the clamps and their bases to the "Babolat" style. I changed the slider 1 main beam to lower and stiffer. And of course counterpart also.

In a one word the hole clamping system.

To clarify, what clamping system are you using: T98 or T92? I know the folks at Stringway would be very interested in understanding the improvements that you made, and to consider any possible upgrades. Can you share some pictures?

I have the T98 clamp system, a pain in the ***. One side glides nicely the other side is sticky sliding on the bar. Had them apart and cleaned etc, but have to keep adjusting to stop the clamps moving. Thank goodness I only string tension mainly at 46 lb. Stringing higher tensions the clamps just move too much. The T98 clamps are just so clunky and not positive. I have used a few other machines and their clamps are so much better. Shame really, my machine is only about 4 years old and I only string my own racquets, plus the odd ones for friends.

In a one word the hole clamping system.

That's more than one word. I'm just sayin...

Joonas

Semi-Pro

I have the T98 clamp system, a pain in the ***. One side glides nicely the other side is sticky sliding on the bar. Had them apart and cleaned etc, but have to keep adjusting to stop the clamps moving. Thank goodness I only string tension mainly at 46 lb. Stringing higher tensions the clamps just move too much. The T98 clamps are just so clunky and not positive. I have used a few other machines and their clamps are so much better. Shame really, my machine is only about 4 years old and I only string my own racquets, plus the odd ones for friends.

Have you tried how many kgs (or lbs) you can pull directly against a clamp? I noticed some turning of swivel under heavy pull. I have not noticed any slippage on rails. I played with tightening until I got it solid under 30kgs load. It makes rail movement little sluggish.

mad dog1

G.O.A.T.

I replaced the main plastic slider with the aluminium one. I changed the clamps and their bases to the "Babolat" style. I changed the slider 1 main beam to lower and stiffer. And of course counterpart also.

In a one word the hole clamping system.

i own a stringway machine that i keep as a backup. so far i haven't had a need to use it since my babolat has been rock solid.

yes, the babolat clamping system is much better, way more rigid, etc. but my babolat machine is a lot pricier than my stringway.

so you get what you pay for. i don't expect my stringway to be as solid of a machine as my babolat given the difference in price.

kudos to you for upgrading your whole clamping system. but i do agree that the clamping system for the sw fixed clamp machines is a bit flimsy with quite a bit of drawback but all the machines i owned except the Prince Neos 1000 and Babolat Sensor had a lot of drawback.

marco forehand

Semi-Pro

I have experience with a number of different machines (ie Ektelon H,Babolat Star 5,Gamma,(can't remember the model#),Stringway EM450 with dual action clamps) and a Stringway ML100 with Stringway flying clamps.

I string between 30 and 50 racquets a month out of my home.

I like my Stringway ML 100 with flying clamps just fine. I sold my EM 450. I have kept my Ektelon (with Wise tension head) for tournament stringing because players assume a drop weight is not as good. Everyone likes to see a power cord and digital read out.

I test my work with a Babolat RDC and a Stringmeter. My customer base is mostly junior and adult tournament players and local teaching pros.I get a consistent stringbed with my set up. Some of my customers notice (not all of them).

I recommend the Concorde system,the ML 100 or the ML 120 with two triple clamps and one double clamp.(The ML 120 with flying clamps would be a special order, I am guessing around $1000.)

Just one man's opinion, not the the final word.

I string between 30 and 50 racquets a month out of my home.

I like my Stringway ML 100 with flying clamps just fine. I sold my EM 450. I have kept my Ektelon (with Wise tension head) for tournament stringing because players assume a drop weight is not as good. Everyone likes to see a power cord and digital read out.

I test my work with a Babolat RDC and a Stringmeter. My customer base is mostly junior and adult tournament players and local teaching pros.I get a consistent stringbed with my set up. Some of my customers notice (not all of them).

I recommend the Concorde system,the ML 100 or the ML 120 with two triple clamps and one double clamp.(The ML 120 with flying clamps would be a special order, I am guessing around $1000.)

Just one man's opinion, not the the final word.

Joonas

Semi-Pro

I have experience with a number of different machines (ie Ektelon H,Babolat Star 5,Gamma,(can't remember the model#),Stringway EM450 with dual action clamps) and a Stringway ML100 with Stringway flying clamps.

I string between 30 and 50 racquets a month out of my home.

I like my Stringway ML 100 with flying clamps just fine. I sold my EM 450. I have kept my Ektelon (with Wise tension head) for tournament stringing because players assume a drop weight is not as good. Everyone likes to see a power cord and digital read out.

I test my work with a Babolat RDC and a Stringmeter. My customer base is mostly junior and adult tournament players and local teaching pros.I get a consistent stringbed with my set up. Some of my customers notice (not all of them).

I recommend the Concorde system,the ML 100 or the ML 120 with two triple clamps and one double clamp.(The ML 120 with flying clamps would be a special order, I am guessing around $1000.)

Just one man's opinion, not the the final word.

Your findings resonate with my results.

I get consistent DT readings with my ERT300 when stringing with both T98 fixed or flying clamps. But when I check mains with Stringmeter there is less (basically no) difference in individual mains string readings whereas there are some differences between individual strings when strung with T98 fixed clamps.

The only reason to this must be minor slippages in swivel clamp base.

I will continue stringing mains with flying clamps (excl. tie off strings if doing 2 piece). For crosses I find T98 to be sufficient.

BlxTennis

Rookie

I have had this machine for a while and clamping system sucks quite badly. They have engineered oddly. They have user plastic in main slider which takes the main load. The result is that clamping isn't stiff enough and the hole clamping system yields way too much. I think when using higher stringing tensions eg. tennis racket stringing the result isn't good enough. It can't be.

I have renewed the hole clamping system and now it is stiff enough and the results are exellent.

The tension system is good. That's why it was worth to renew the clamping system.

The way I have done the clamping system is way too expensive to do in a commercial meaning. Lots of machined parts eg. The original system is made by standard bars avoiding machining.

Hm...I have T92 clamp system and it doesn't "yield way too much". If you look at the following thread, Fig19 shows you can minimize drawback by pushing top in the direction where string will be pulled after releasing tension head. I push the bottom instead and the drawback is very little like 2mm. Is that too much? What exactly improvement have you done? Can you share with some photos?

http://tt.tennis-warehouse.com/showthread.php?t=461190&page=6

My machine is in some of the photos in this thread:

http://tt.tennis-warehouse.com/showthread.php?t=461190

My Stringway system is under construction

Will return with the photos when I get it done!!!

My ML100 does't have that kind of bar in side slider (for cross strings).

It's like one below.

I have done that backslash elimination as mentioned but it doesn't help when the hole system is yielding.

One thing which was making the clamping much stiffer was replacing the plastic slider with the aluminium one. Stringing mains was a different story after that. No drawback at all.

Hm...I have T92 clamp system and it doesn't "yield way too much". If you look at the following thread, Fig19 shows you can minimize drawback by pushing top in the direction where string will be pulled after releasing tension head. I push the bottom instead and the drawback is very little like 2mm. Is that too much? What exactly improvement have you done? Can you share with some photos?

http://tt.tennis-warehouse.com/showthread.php?t=461190&page=6

My machine is in some of the photos in this thread:

http://tt.tennis-warehouse.com/showthread.php?t=461190

Will return with the photos when I get it done!!!

My ML100 does't have that kind of bar in side slider (for cross strings).

It's like one below.

I have done that backslash elimination as mentioned but it doesn't help when the hole system is yielding.

One thing which was making the clamping much stiffer was replacing the plastic slider with the aluminium one. Stringing mains was a different story after that. No drawback at all.

BlxTennis

Rookie

Will return with the photos when I get it done!!!

My ML100 does't have that kind of bar in side slider (for cross strings).

It's like one below.

I have done that backslash elimination as mentioned but it doesn't help when the hole system is yielding.

One thing which was making the clamping much stiffer was replacing the plastic slider with the aluminium one. Stringing mains was a different story after that. No drawback at all.

Excellent. Would love to see what/how you replace the slider on the bar with aluminum one. Please take some photos and how you did the replacement work. Thanks.

Not the rocket science

I just cut 46 mm piece of 40 mm aluminium bar and made main 20 mm hole and two M6 holes for socket head screws as they were in an original plastic slider.

Only little bit demanding thing was that the 20 mm hole must be quite accurate, 20 +0.1 +0.05 will do.

Sending photos here is little bit odd because you have to hava a URL-address of the photo and I don't know how to do that. All my photos are in my PC.

Excellent. Would love to see what/how you replace the slider on the bar with aluminum one. Please take some photos and how you did the replacement work. Thanks.

I just cut 46 mm piece of 40 mm aluminium bar and made main 20 mm hole and two M6 holes for socket head screws as they were in an original plastic slider.

Only little bit demanding thing was that the 20 mm hole must be quite accurate, 20 +0.1 +0.05 will do.

Sending photos here is little bit odd because you have to hava a URL-address of the photo and I don't know how to do that. All my photos are in my PC.

I have the T98 clamp system, a pain in the ***. One side glides nicely the other side is sticky sliding on the bar. Had them apart and cleaned etc, but have to keep adjusting to stop the clamps moving. Thank goodness I only string tension mainly at 46 lb. Stringing higher tensions the clamps just move too much. The T98 clamps are just so clunky and not positive. I have used a few other machines and their clamps are so much better. Shame really, my machine is only about 4 years old and I only string my own racquets, plus the odd ones for friends.

I've got a few suggestions for you. I've got an ML100 with T98s. Over time the glide bars need to be cleaned/lubed and the clamps may need adjusting. (Which I know you've tried.) I have found that using denatured alcohol and a cotton cloth on the bars will clean residue up nicely. I don't recommend mineral spirits (paint thinner), as that contains petroleum distillates that remain on the bar. Once you have them cleaned well with the denatured alcohol, apply a thin coat of spray silicone and work the clamps back and forth across the bars a few times. In my experience the clamps will glide freely once again.

Regarding adjustments to the clamps, it is important to ensure that the lever always reaches its full top/end position when clamped. Only then it is stable. To achieve that make sure the adjusting nut at the bottom is only adjusted with the lever in its full top/end position. If the nut is adjusted while not fully clamped, the lever cannot pass the vertical position and its stability is compromised.

This is from the manual: "With double action system T98 the string is clamped first and after that the system is clamped on the guiding rails and in rotational direction by switching the handle (fig.16). "The clamping force of the guiding system can be adjusted with the nut (fig.17)."

VERY IMPORTANT:

- The clamping force on the rail should only be adjusted with the handle in the VERTICAL end position.

- During use the handle should always reach the vertical end position to be stable.

Here's an image of the adjusting nut location: http://imagizer.imageshack.us/a/img402/1874/t98geb2.jpg

Hope that helps.

BlxTennis

Rookie

I just cut 46 mm piece of 40 mm aluminium bar and made main 20 mm hole and two M6 holes for socket head screws as they were in an original plastic slider.

Only little bit demanding thing was that the 20 mm hole must be quite accurate, 20 +0.1 +0.05 will do.

Sending photos here is little bit odd because you have to hava a URL-address of the photo and I don't know how to do that. All my photos are in my PC.

You can get an account from Photobucket dot com then you can just insert link from here.

Joonas

Semi-Pro

I've got a few suggestions for you. I've got an ML100 with T98s. Over time the glide bars need to be cleaned/lubed and the clamps may need adjusting. (Which I know you've tried.) I have found that using denatured alcohol and a cotton cloth on the bars will clean residue up nicely. I don't recommend mineral spirits (paint thinner), as that contains petroleum distillates that remain on the bar. Once you have them cleaned well with the denatured alcohol, apply a thin coat of spray silicone and work the clamps back and forth across the bars a few times. In my experience the clamps will glide freely once again.

Regarding adjustments to the clamps, it is important to ensure that the lever always reaches its full top/end position when clamped. Only then it is stable. To achieve that make sure the adjusting nut at the bottom is only adjusted with the lever in its full top/end position. If the nut is adjusted while not fully clamped, the lever cannot pass the vertical position and its stability is compromised.

This is from the manual: "With double action system T98 the string is clamped first and after that the system is clamped on the guiding rails and in rotational direction by switching the handle (fig.16). "The clamping force of the guiding system can be adjusted with the nut (fig.17)."

VERY IMPORTANT:

- The clamping force on the rail should only be adjusted with the handle in the VERTICAL end position.

- During use the handle should always reach the vertical end position to be stable.

Here's an image of the adjusting nut location: http://imagizer.imageshack.us/a/img402/1874/t98geb2.jpg

Hope that helps.

Thanks 10sDad! This for sure helps! I noticed the importance of FULL vertical posititon.

Irvin

Talk Tennis Guru

Works quite well.

Actually it does not. The way you did it someone can go to your link and scan through all your photos. That's not good if you know what I mean. I would have the admin edit your post or you could get in trouble.

MAX PLY

Hall of Fame

Actually it does not. The way you did it someone can go to your link and scan through all your photos. That's not good if you know what I mean. I would have the admin edit your post or you could get in trouble.

Ooops. But happy for the chuckle.

Ok

How that photo sharing should be done in Photobucket? It's quite new thing for me.

Actually it does not. The way you did it someone can go to your link and scan through all your photos. That's not good if you know what I mean. I would have the admin edit your post or you could get in trouble.

How that photo sharing should be done in Photobucket? It's quite new thing for me.

Irvin

Talk Tennis Guru

How that photo sharing should be done in Photobucket? It's quite new thing for me.

I believe you need to have 50 posts before you can post photos. But if you can you have to got to your library and get the link for sharing in photobucket and post that link in TW.

Thanks

No photos from me to this forum.

I believe you need to have 50 posts before you can post photos. But if you can you have to got to your library and get the link for sharing in photobucket and post that link in TW.

No photos from me to this forum.

Similar threads

- Replies

- 19

- Views

- 8K

- Replies

- 13

- Views

- 4K

- Replies

- 14

- Views

- 4K

- Replies

- 18

- Views

- 981

- Replies

- 2

- Views

- 690